Architecture was confined and restricted by the means of constructions. As a result, architects and builders developed many techniques to achieve for construction that allowed the design to evolve and be more complex. Through the time, designers and architect started to take initiative and produce the utmost complex geometry that builders couldn’t handle. The designers now have to design the method of construction and the way it could be built through iterative process known as design research.

Now architects are actually designing the systems and technology that allow them to build their projects first. Then produce variations of the design that would take a lot of research and collaboration with the manufacturing industry to execute. The gap between design and fabrication narrowed significantly since both architects and builders are contributing to it. What made this gap even narrower is the accuracy of design and how comprehensive it is. Computers played big role to simulate every single aspect of the design to make sure of it safety and functionality. With that, the translation of the digital model into physical has to happen somehow.

Through advancement of technology, additive manufacturing process, also known as 3D printing, is able to execute complex design, and digitally do all the calculations needed to literal translation. That process narrows down the human execution errors and save a lot of time.

01. Conventional Wall

02. Discrete design technique

03. Definition of Geometry

04. Topology Emphasis

05. Definition of Functions

06. Articulation through Materia; Reduction

07. Structural Optimization

08. Surface Tectonics

09. Final Detailing

Balancing and center of gravity

Functioning partition and designated program

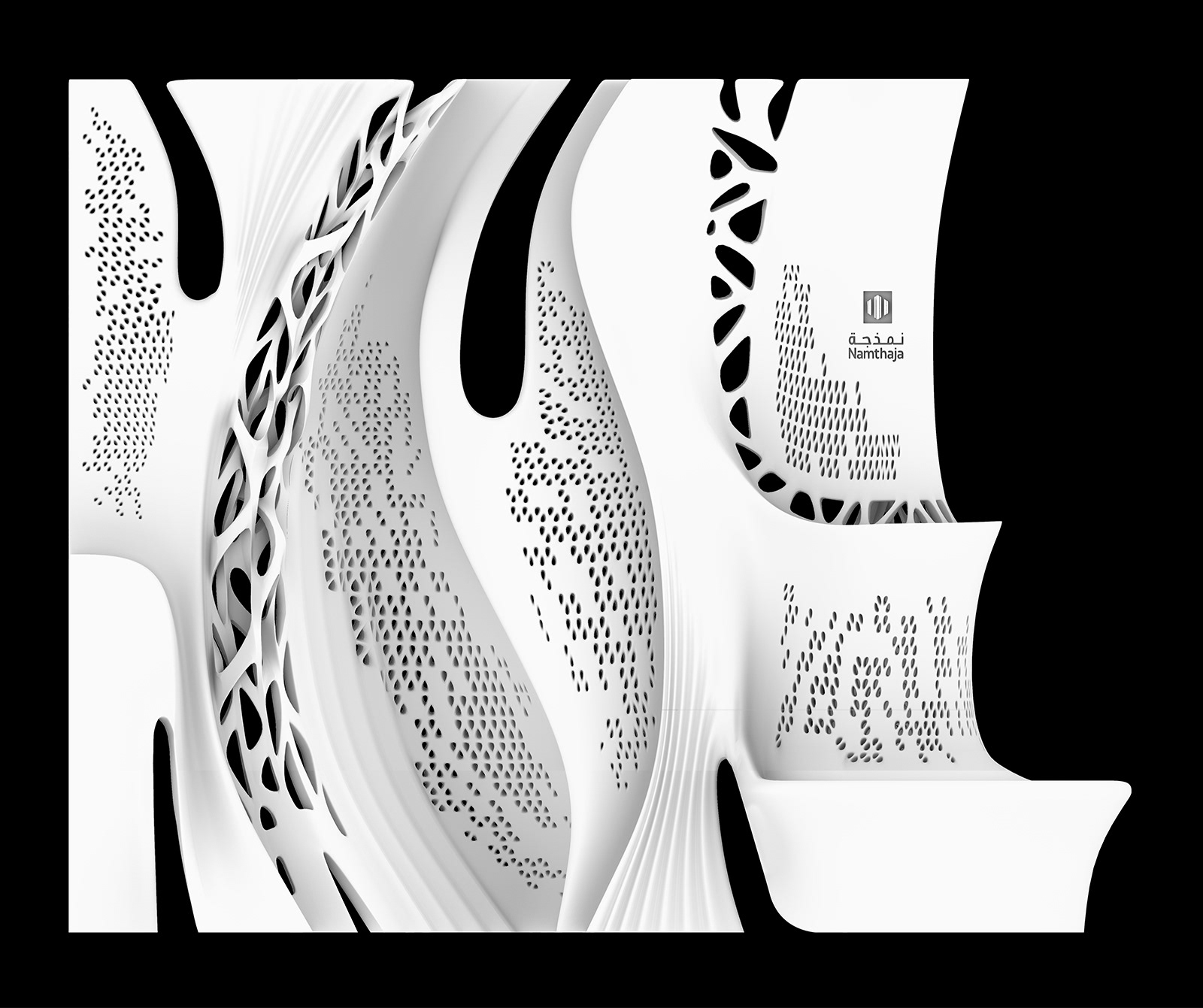

3D Printed Study Model

Surface Details

Curvature Details

Interlocked Frames

Geometry Integration

Single piece small 3D printed scale prototype model

Actual 3D printed parts (13 pieces in total)