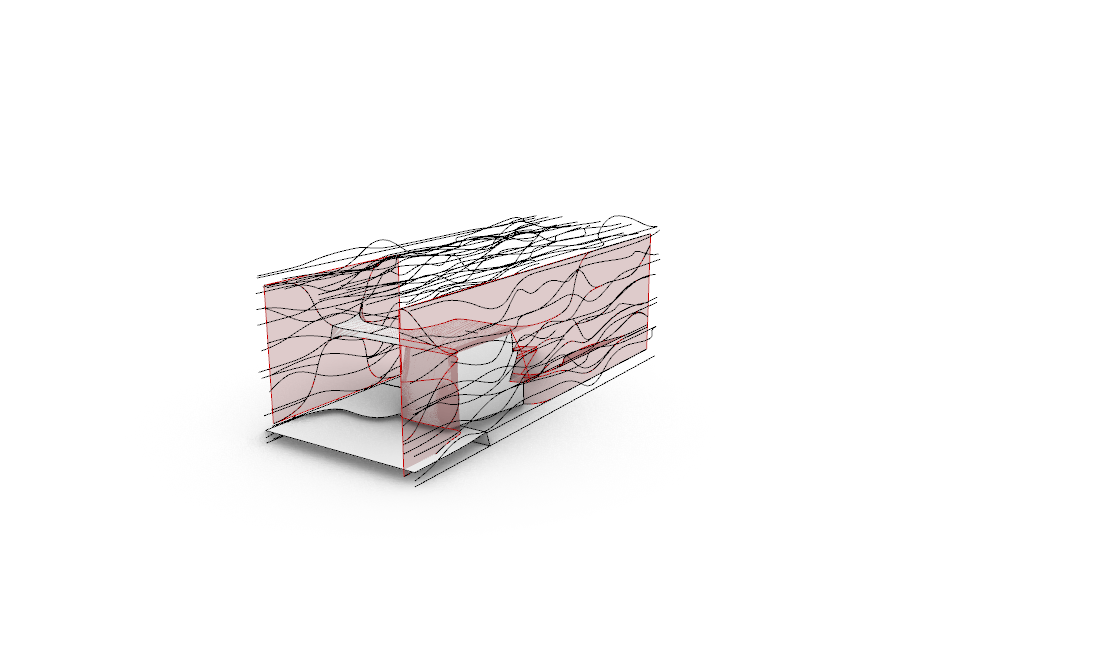

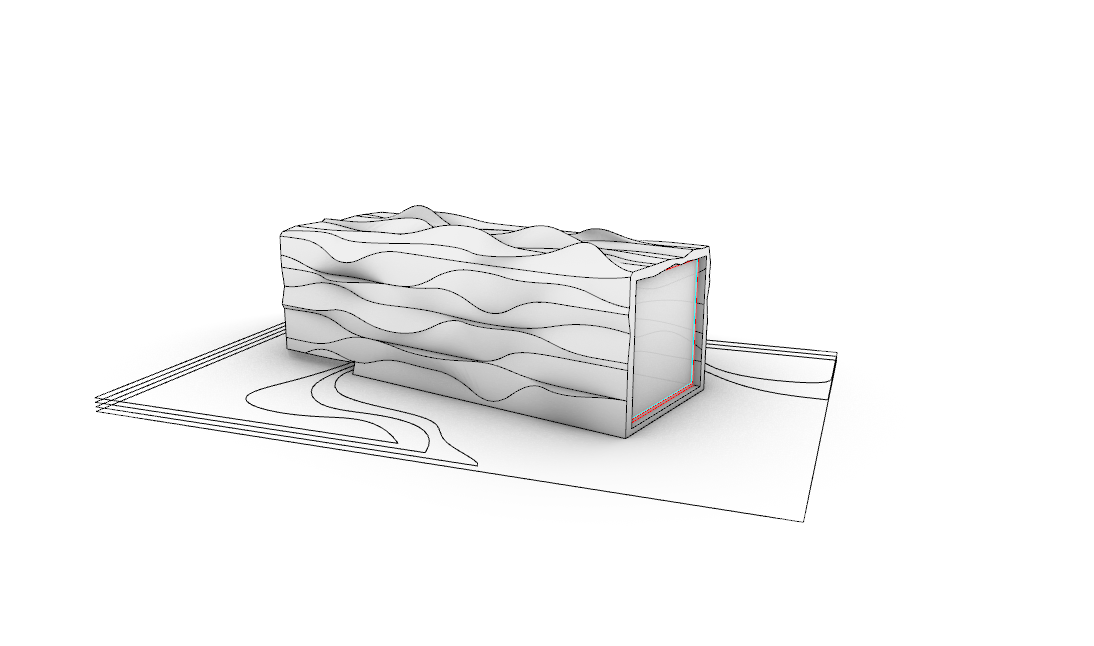

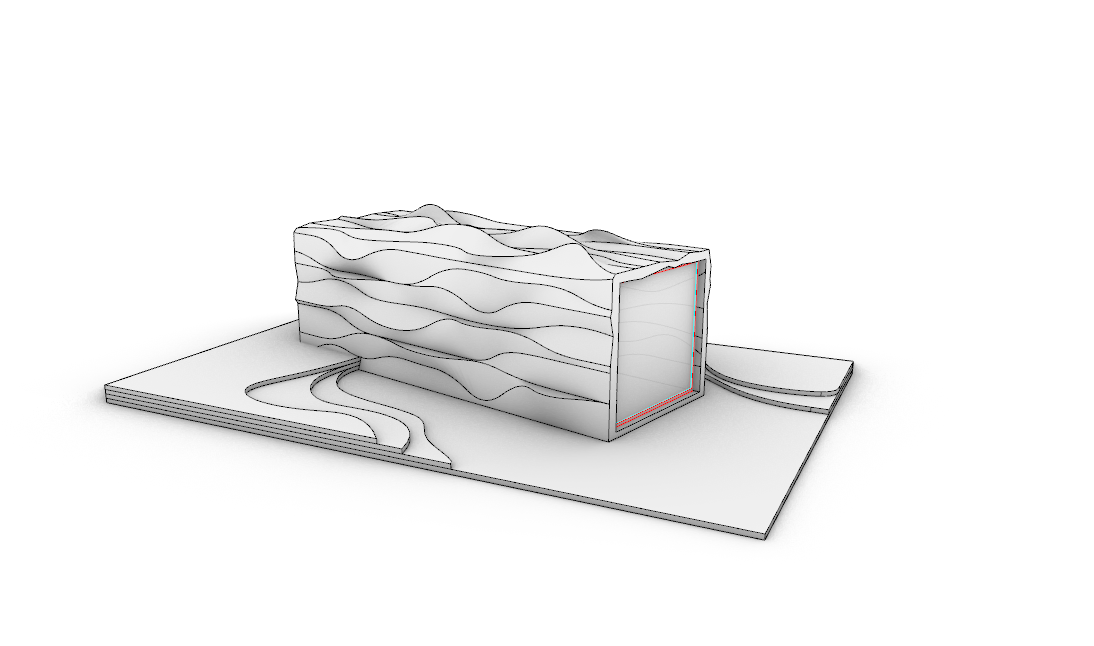

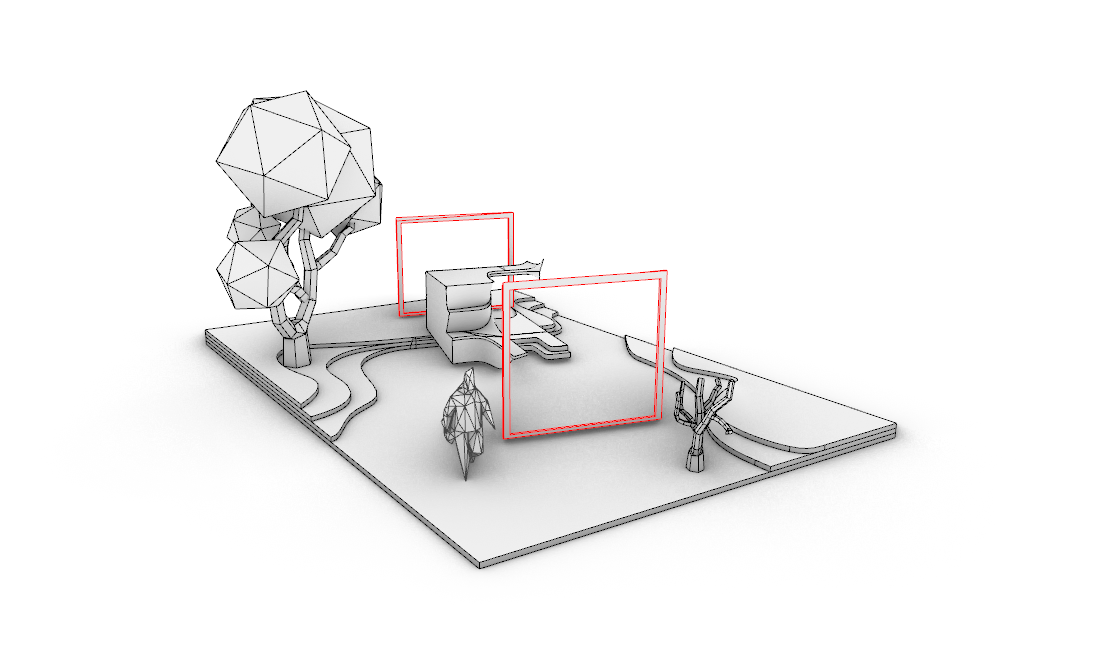

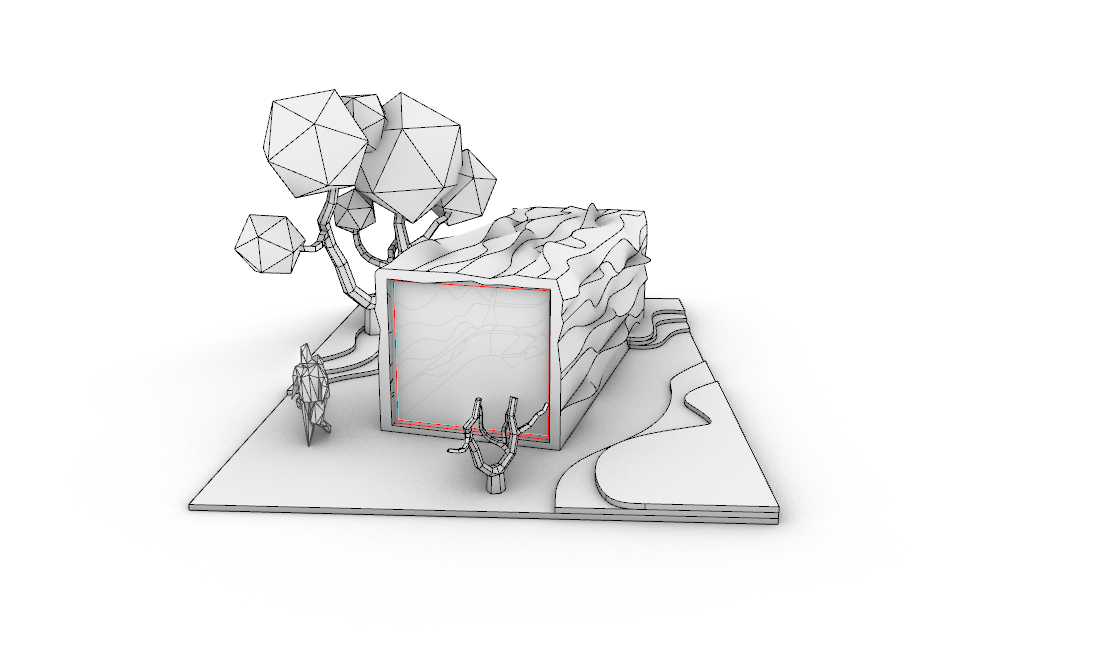

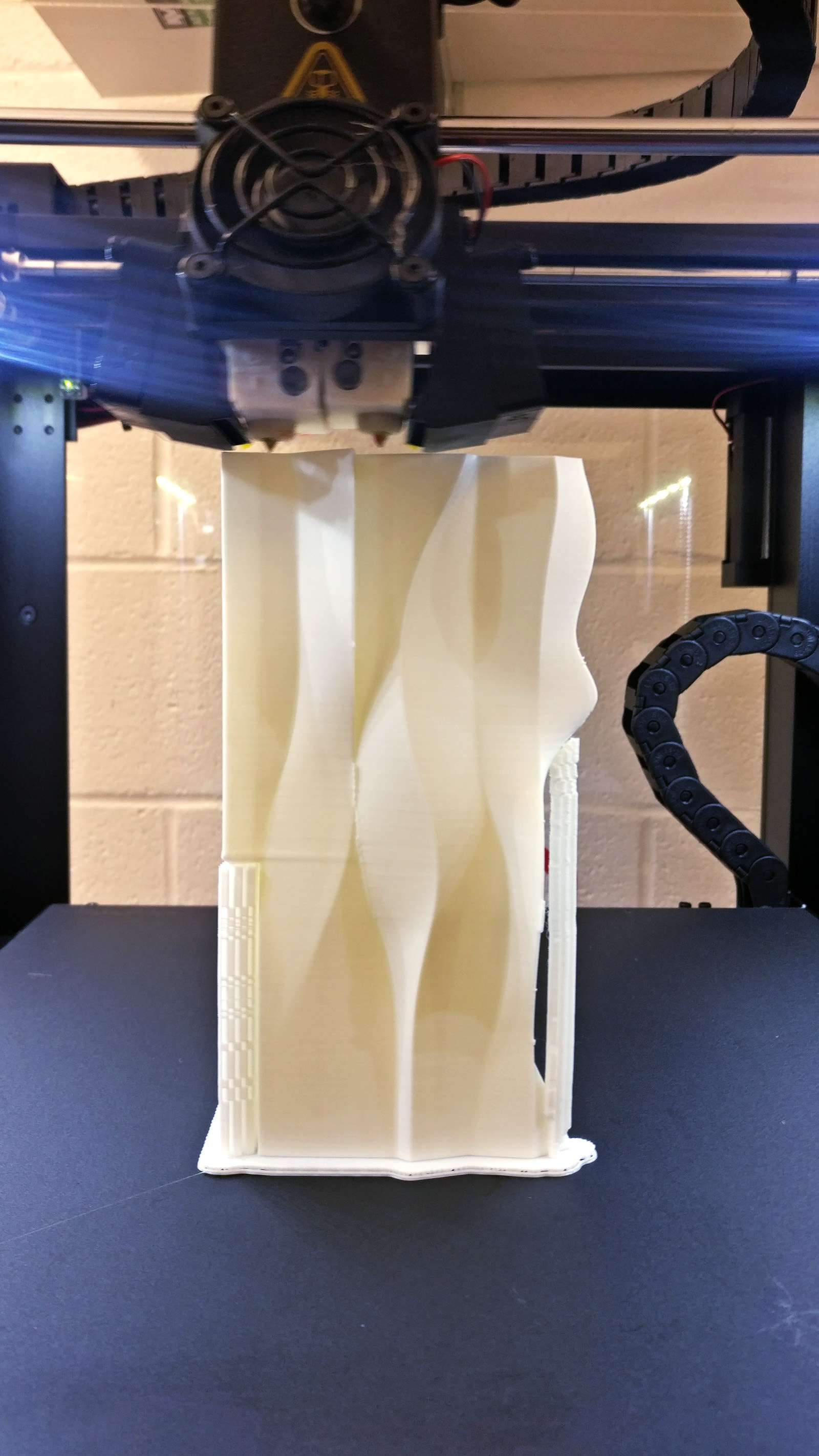

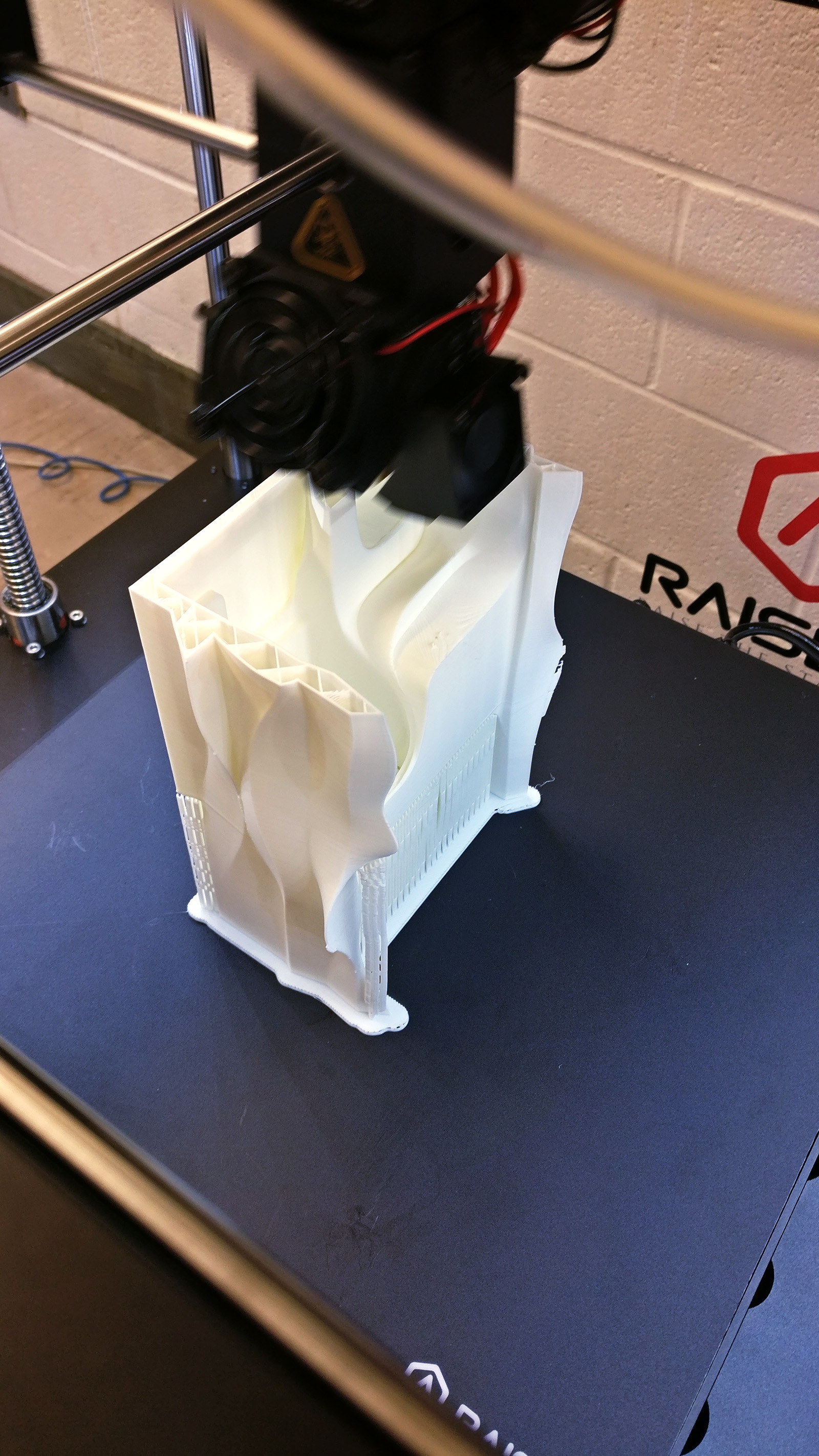

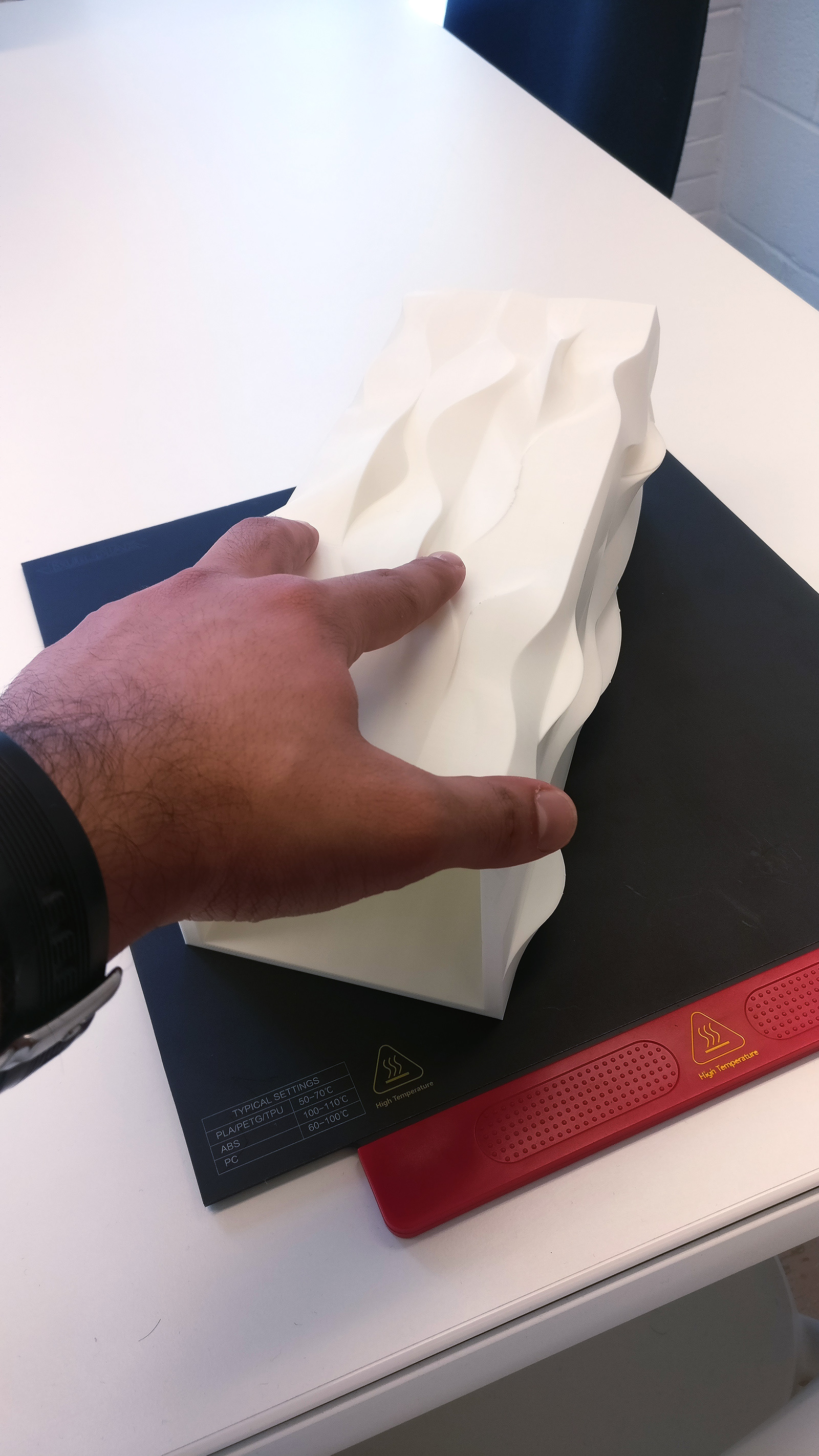

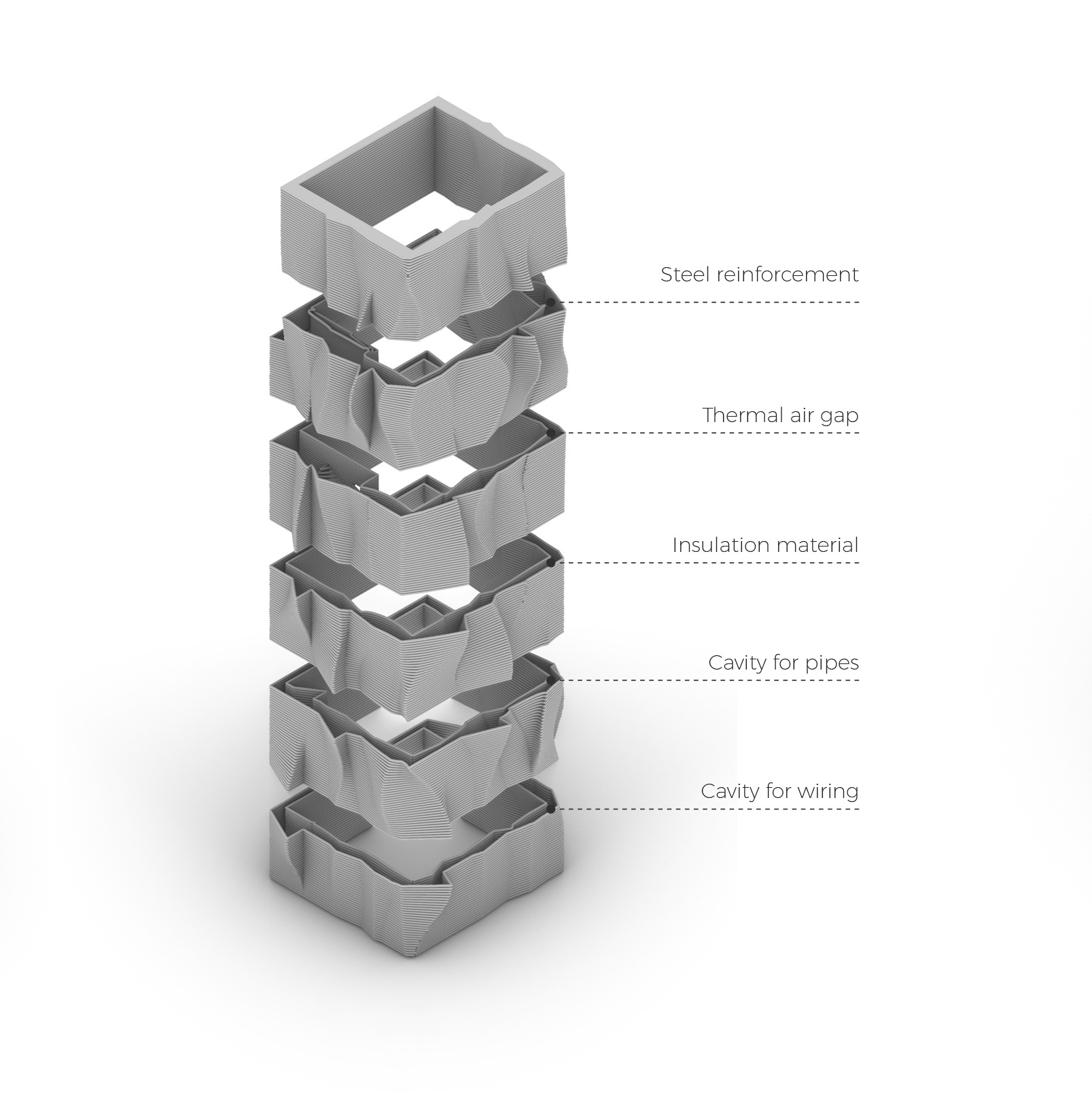

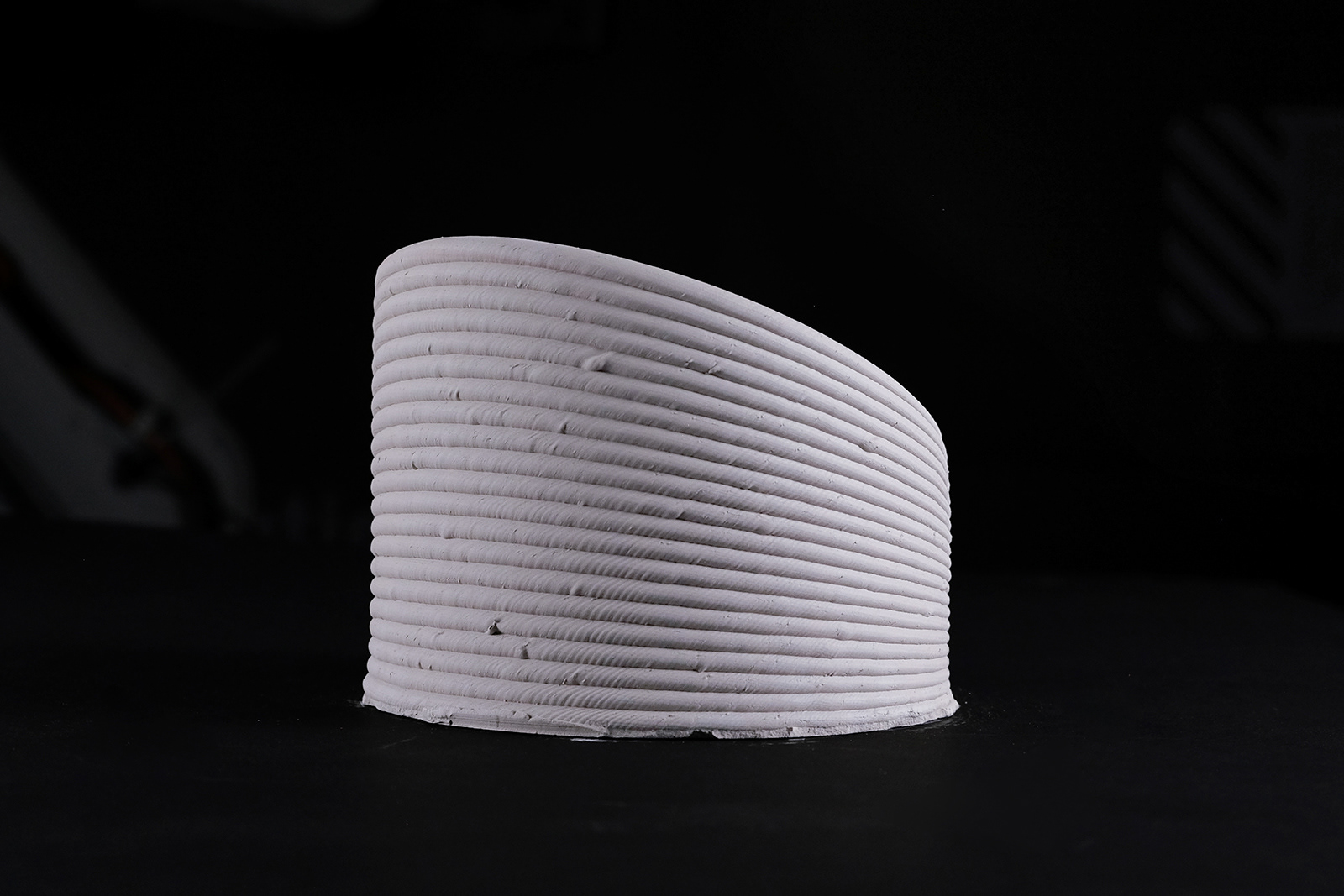

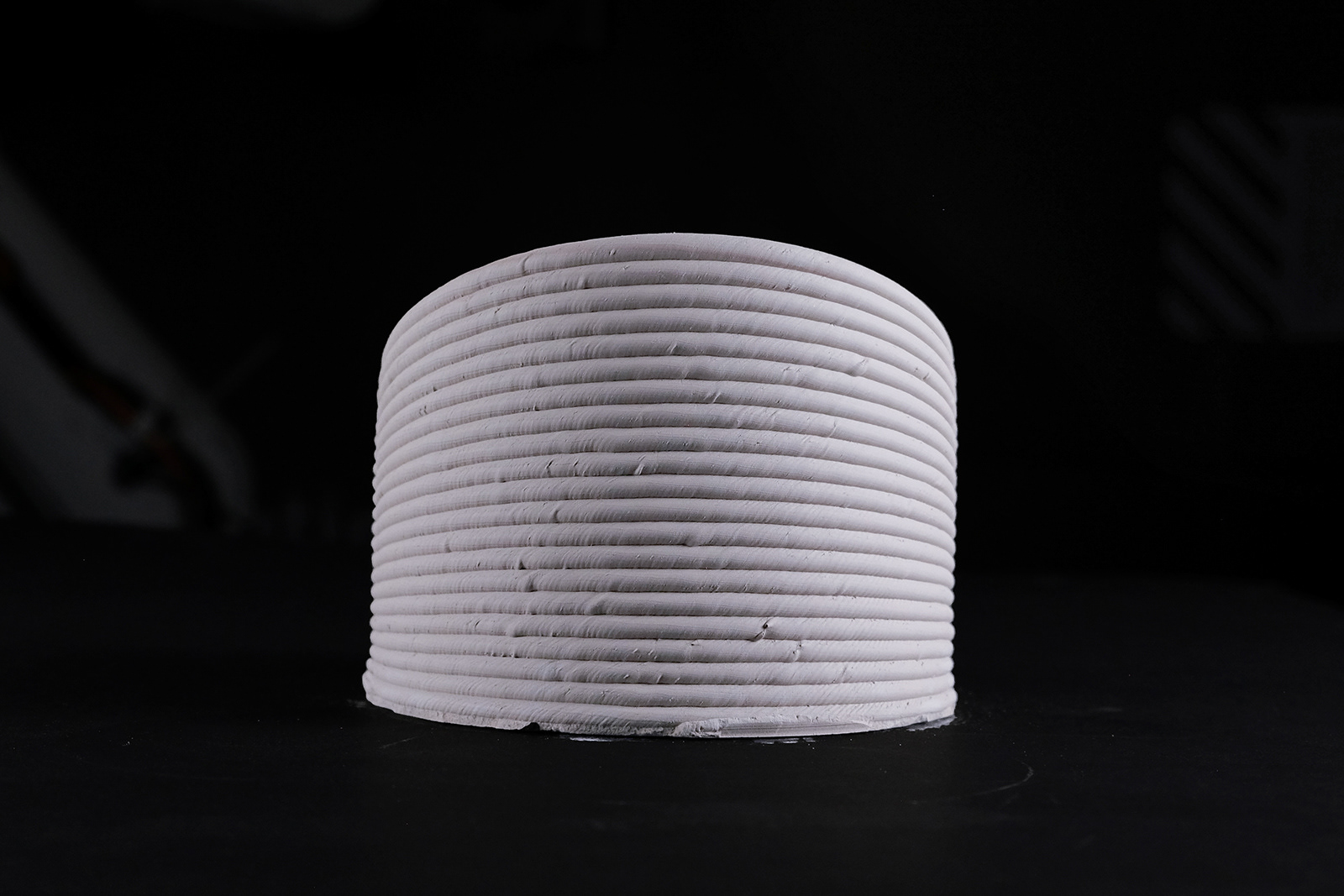

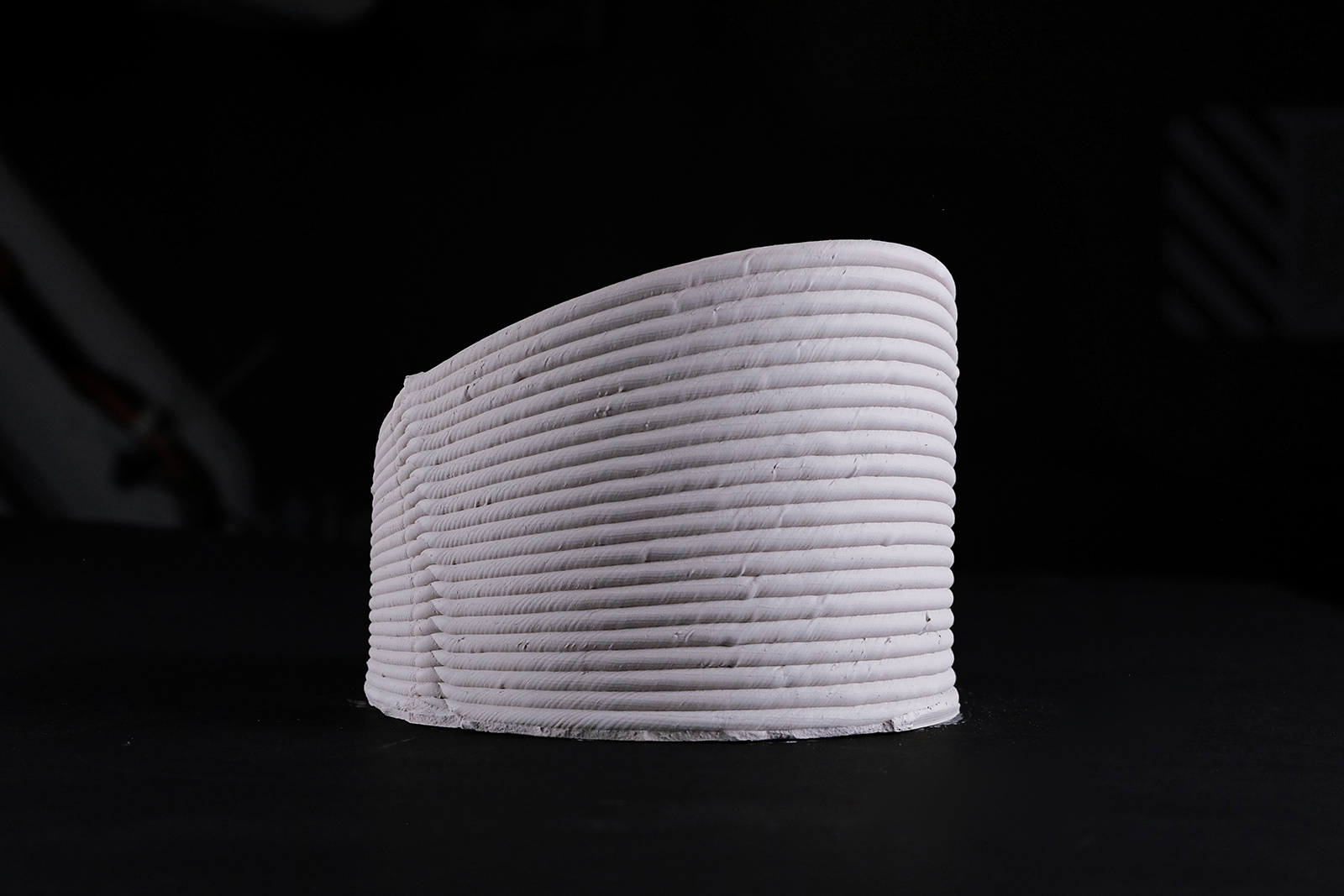

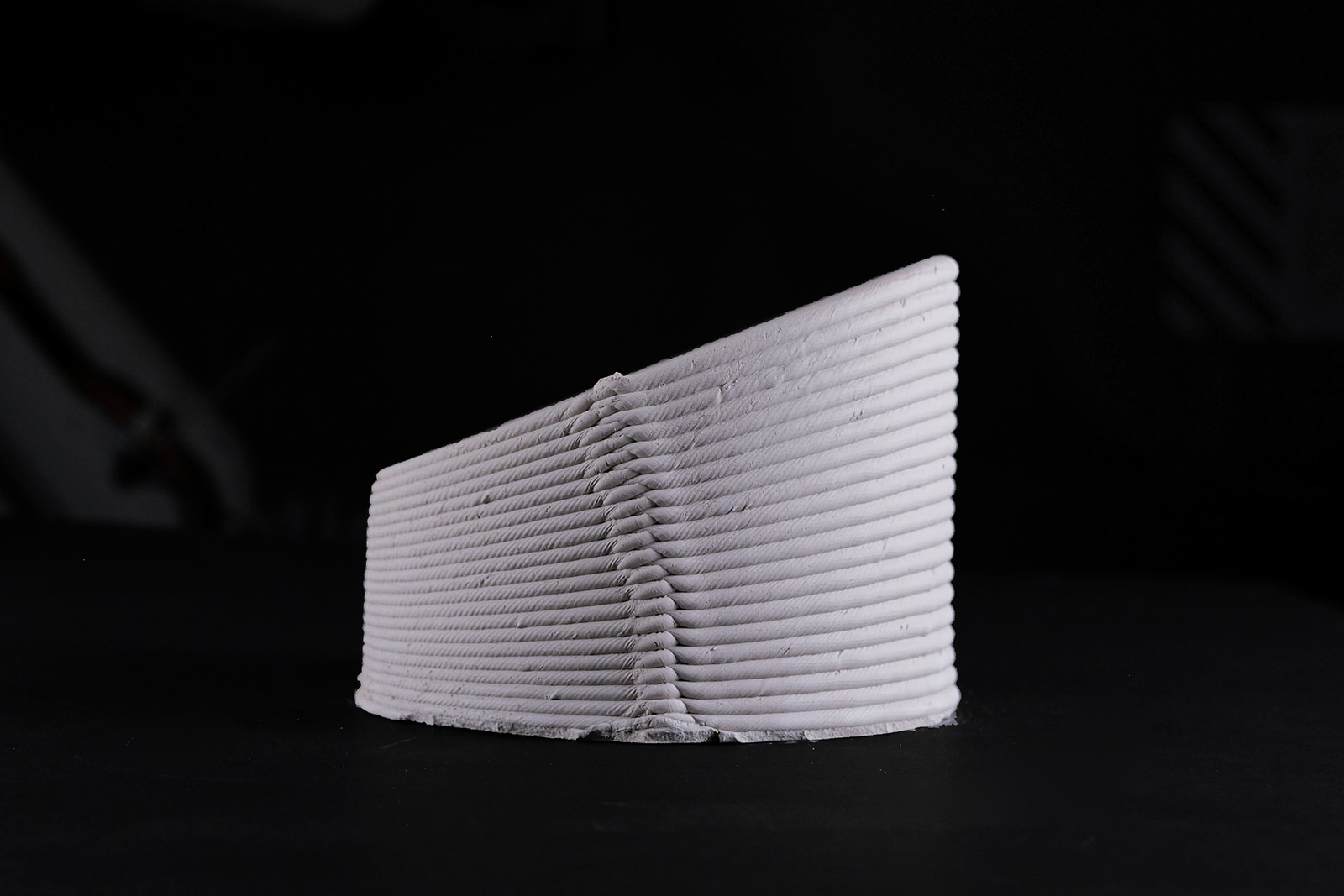

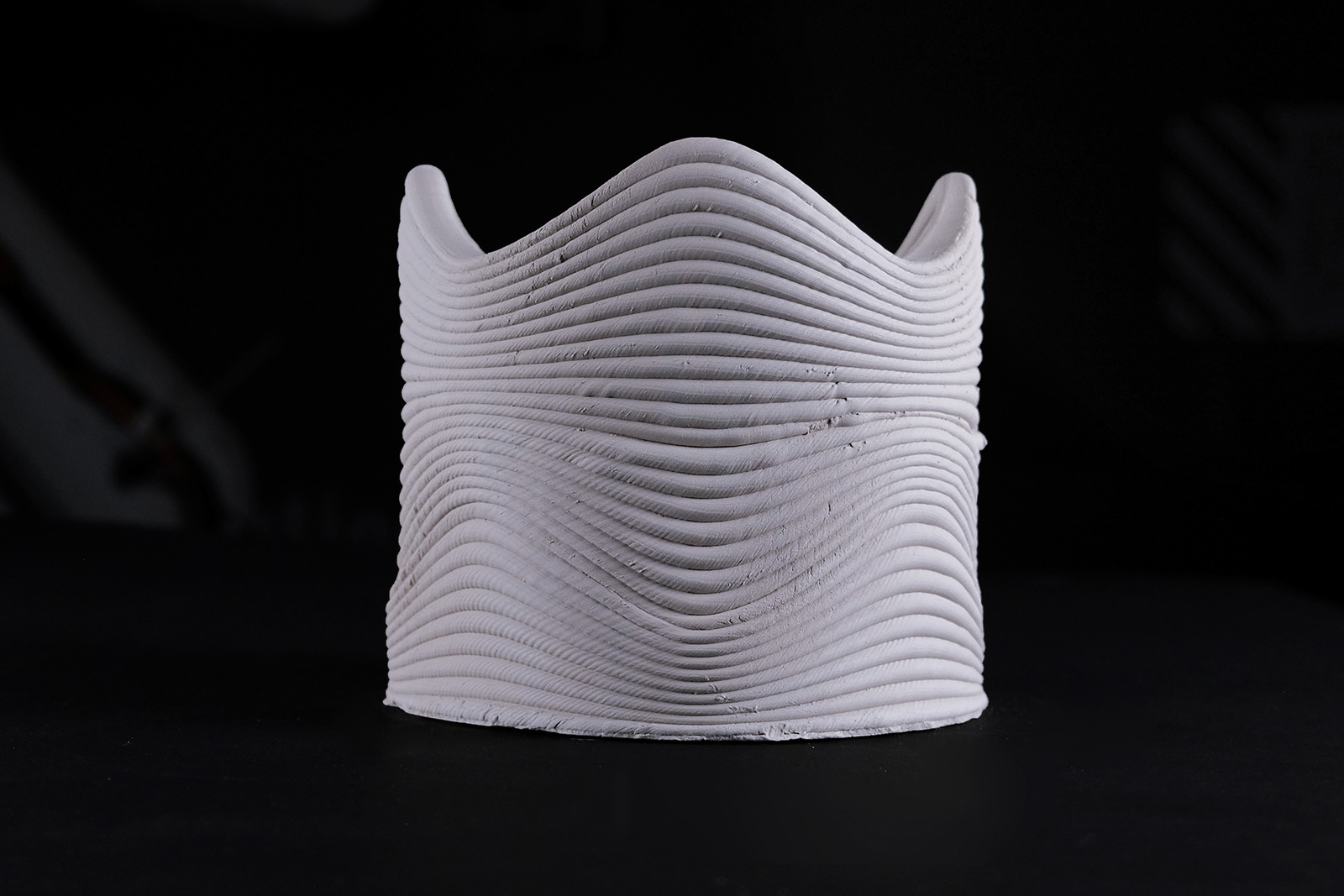

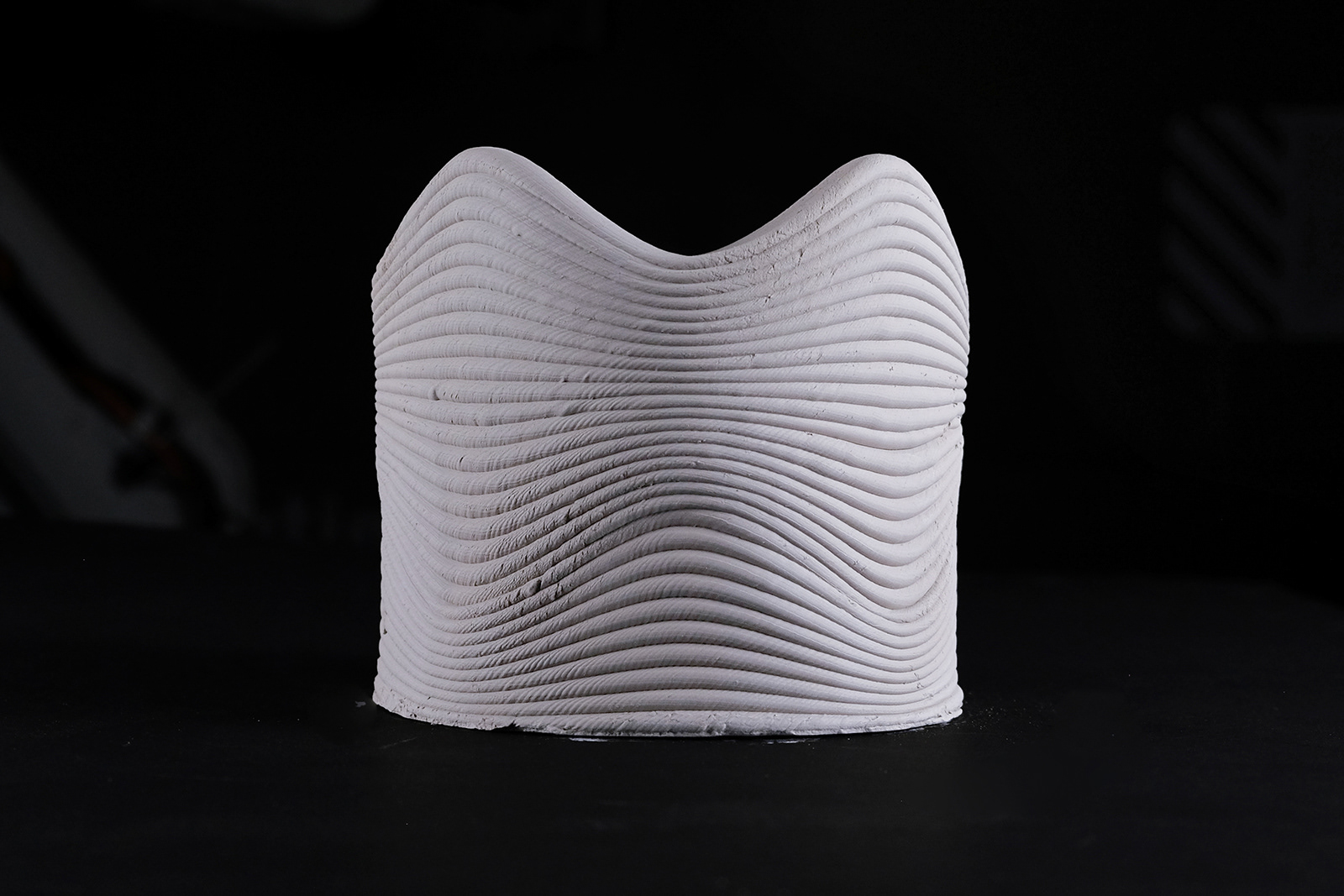

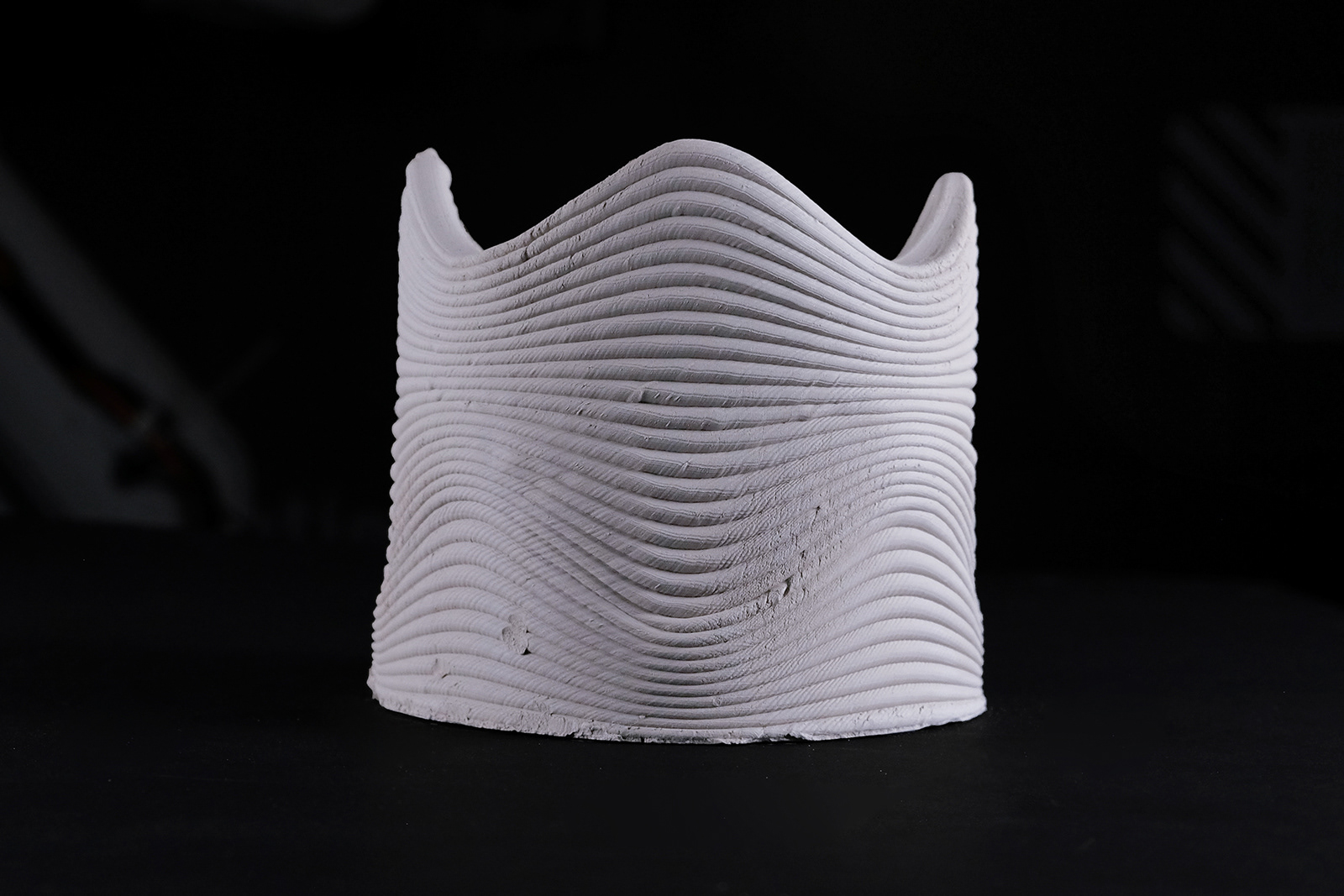

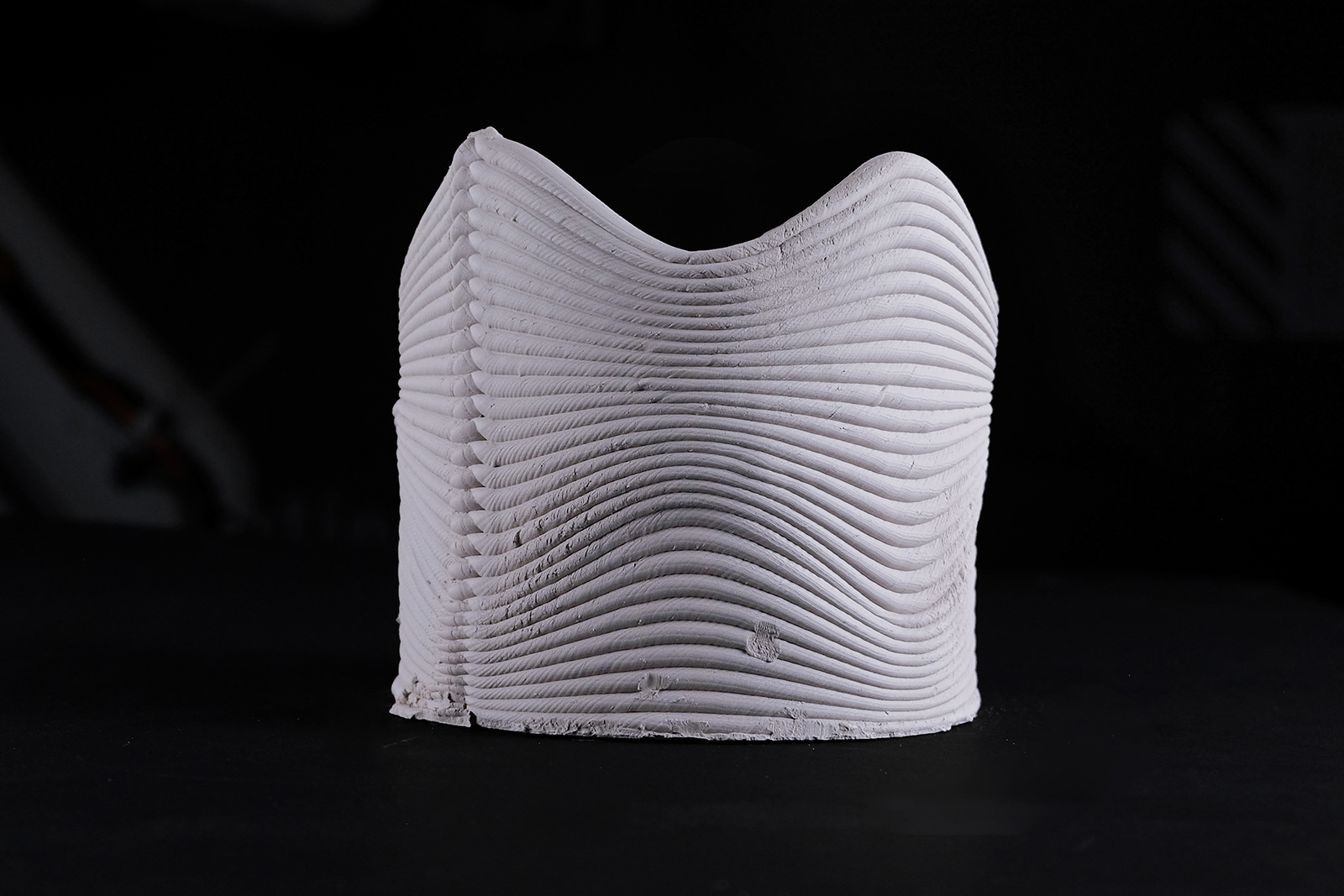

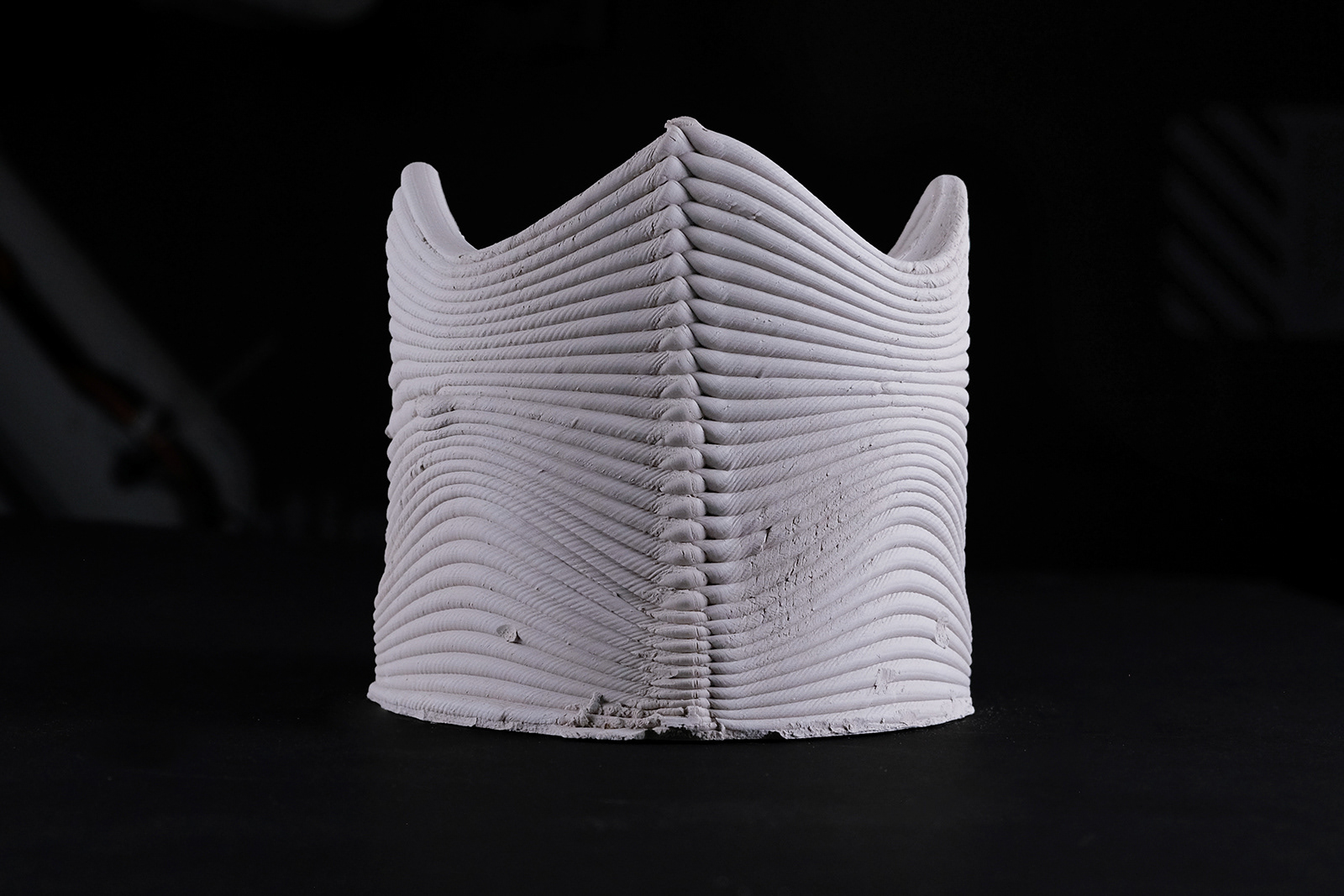

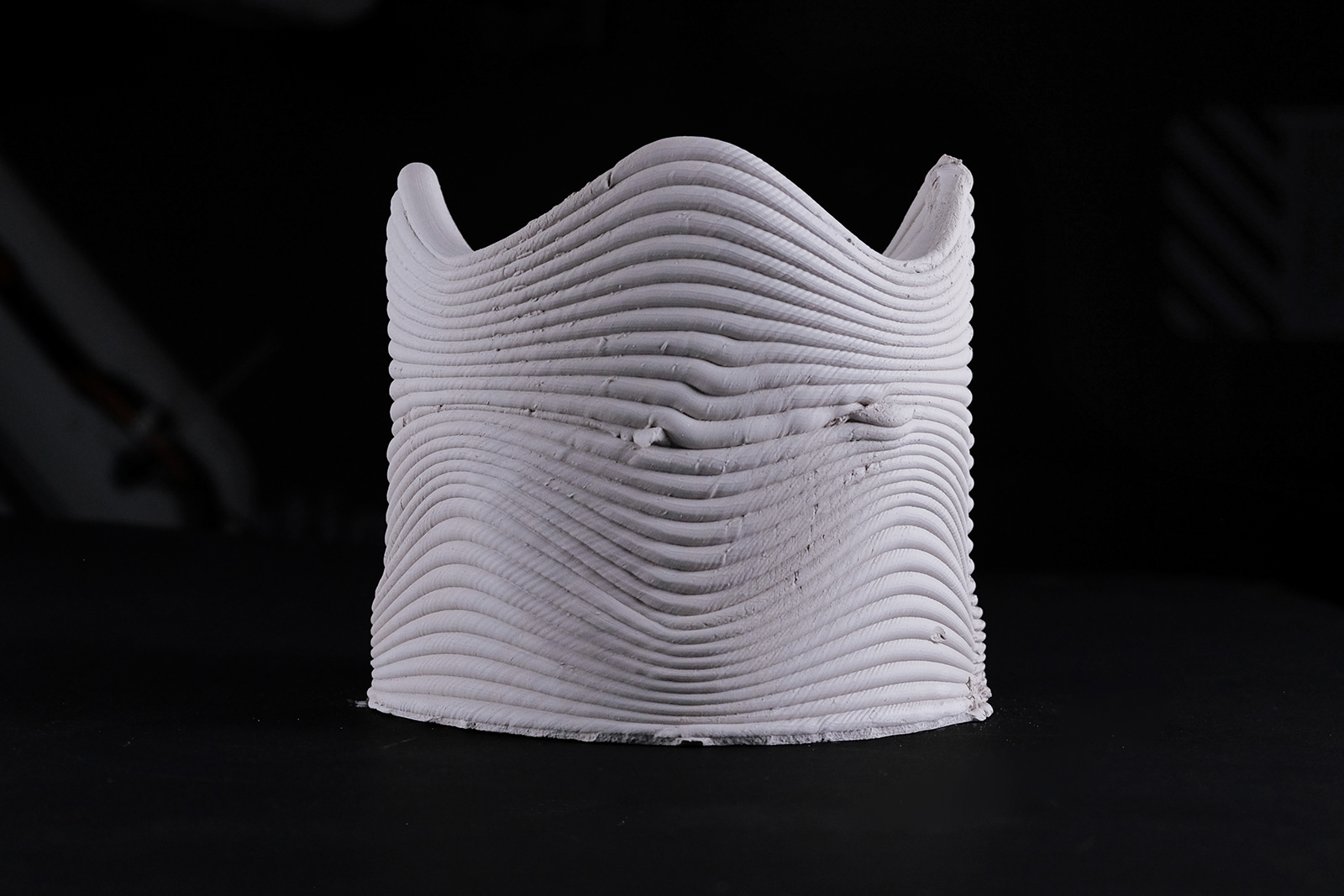

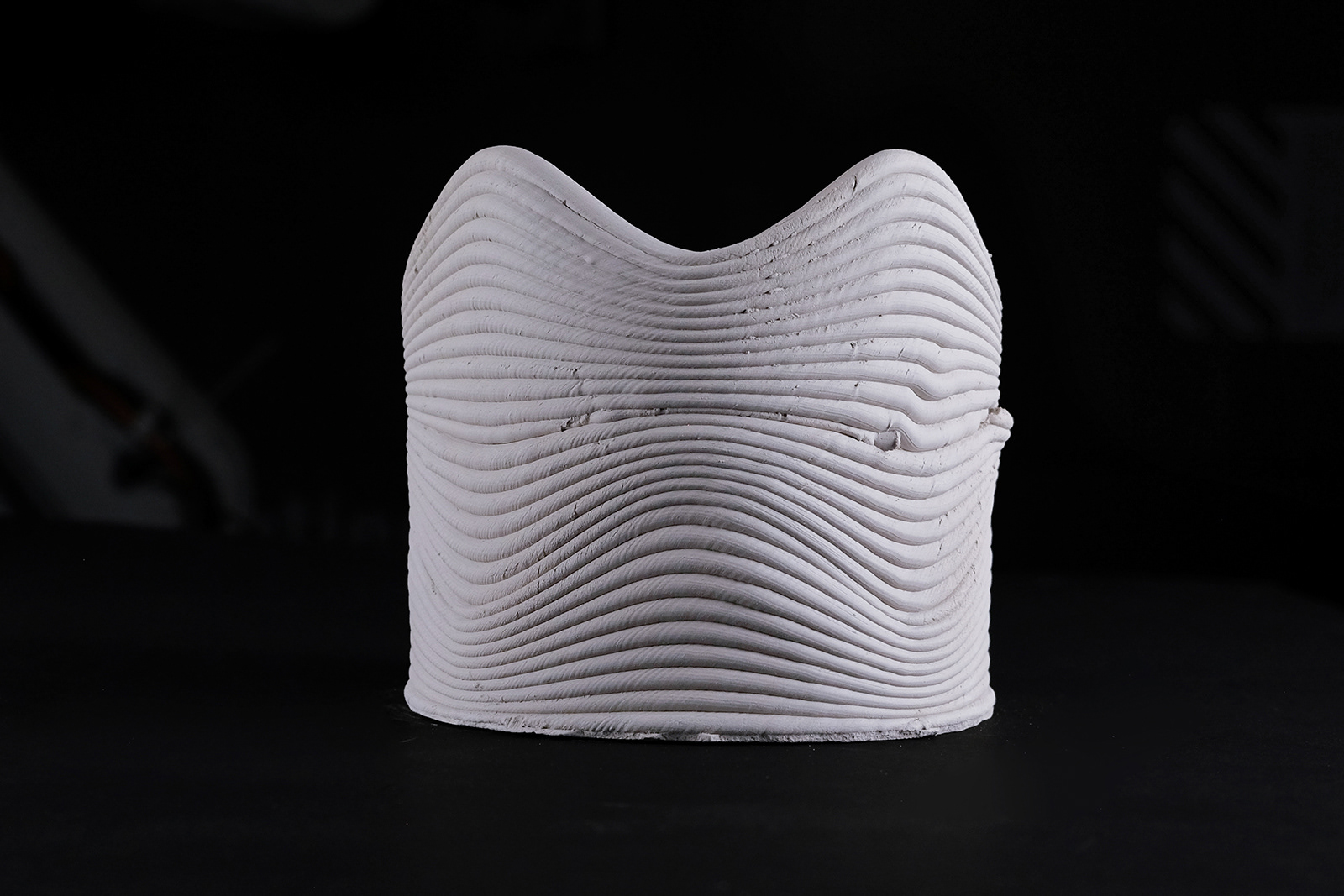

A ground-breaking robotic manufacturing technology in architecture and construction. Inspired by the rapid change in construction, digital solutions and the aspiring vision of the city of the future, NEOM. This prototype is fundamentally started from research labs and it is continuing to collaborate with advanced research institutions in the USA and Europe along with local manufacturers. The goal is to produce intelligent, eco-friendly, and futuristic living spaces through a computational process in shorter time, lower costs, and at the highest quality of living. The future of construction is shifting towards automation and autonomous manufacturing systems, and this will soon become the industrial standards.

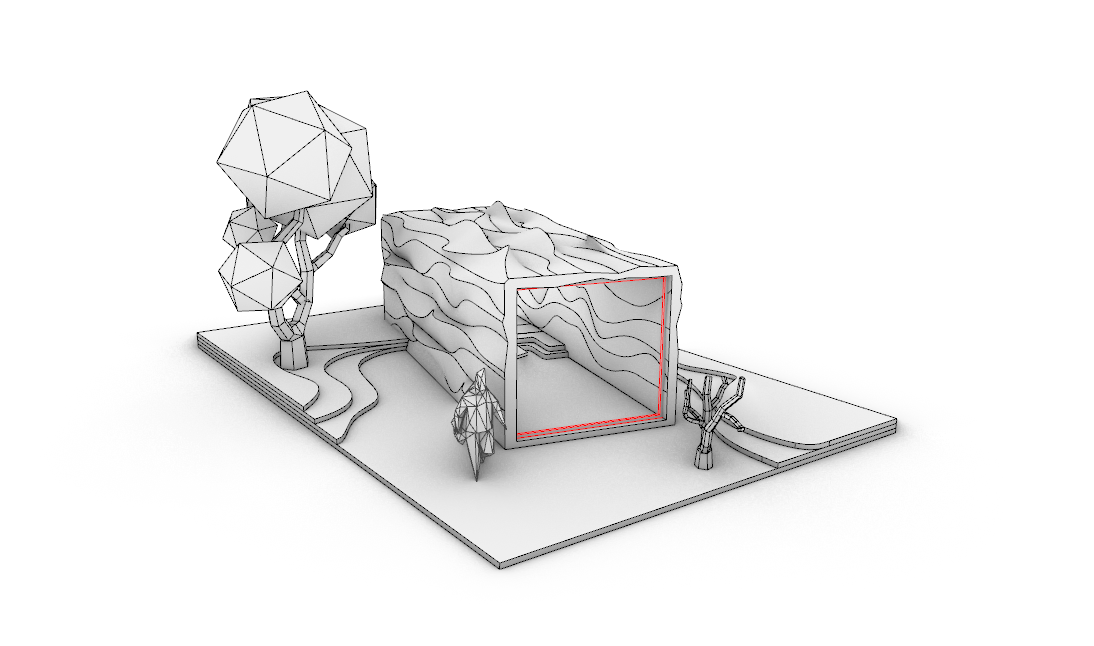

Limitless tool attachment:

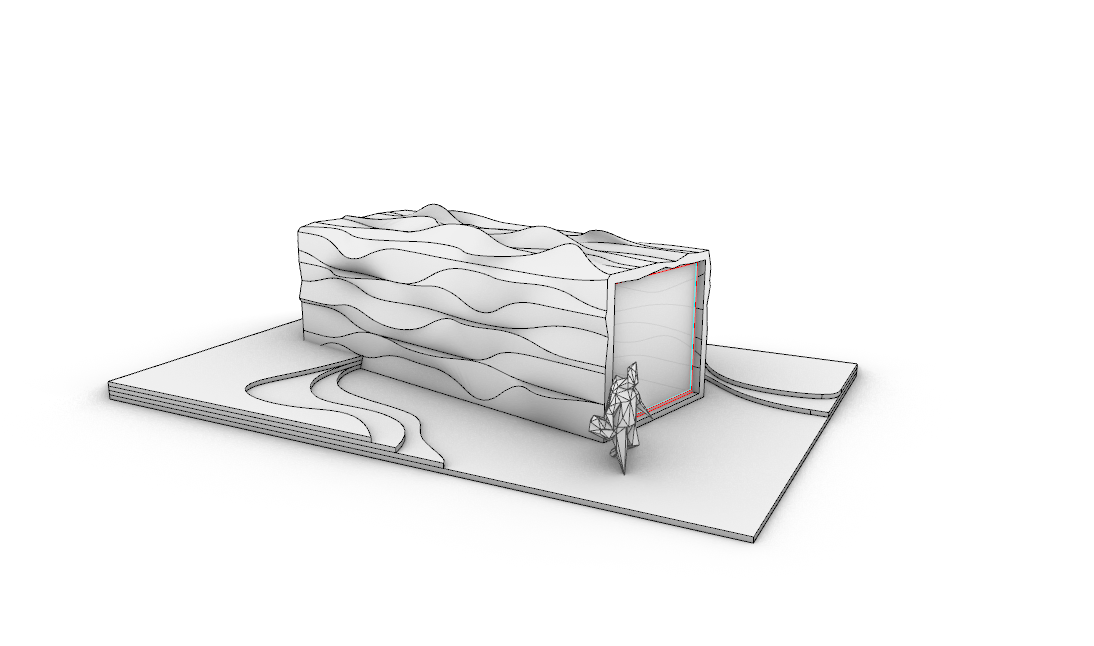

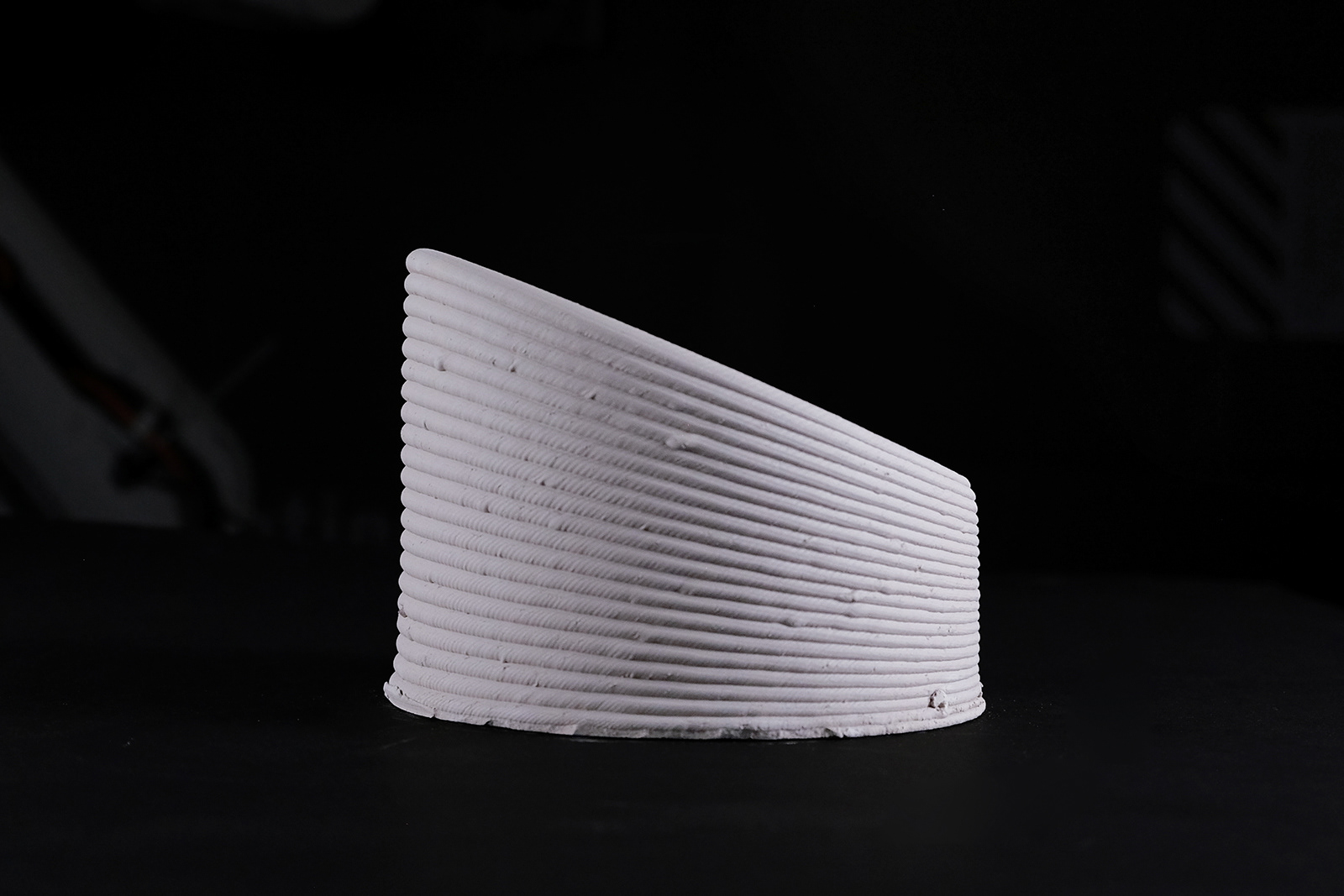

As the Robot is basically an arm with 6 degrees of freedom, it is capable of moving the end point in any range. That is the position of specific point in space that tool would perform something. The tools mostly custom designed for every purpose, but it uses the motion control. The tool is performing a different task from the robot, yet they are digitally integrated in the sequence of command.

As the Robot is basically an arm with 6 degrees of freedom, it is capable of moving the end point in any range. That is the position of specific point in space that tool would perform something. The tools mostly custom designed for every purpose, but it uses the motion control. The tool is performing a different task from the robot, yet they are digitally integrated in the sequence of command.

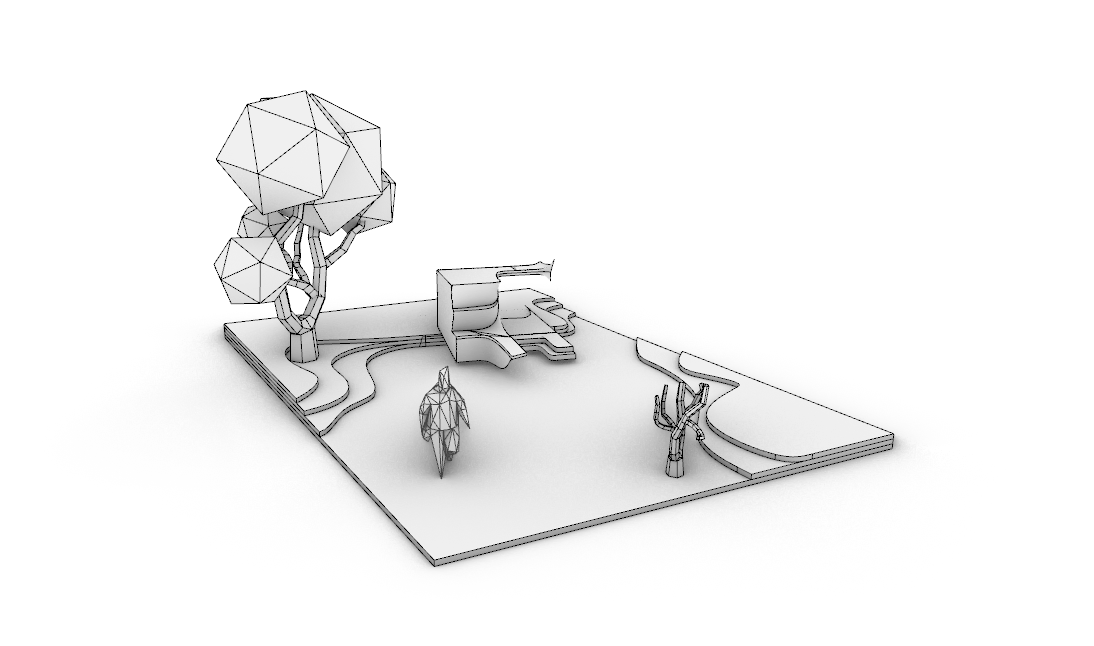

Adaptable and develop-able:

It is never obsolete. The robot is the arm and it would do as instructed. The boundaries of what it is capable of is wider than anticipated. As the industry evolves and develops, the tools could be easily upgraded and or replaced, yet the main machine still as is. Updating the robot program or software always keeps up to date the most advanced process it could be.

It is never obsolete. The robot is the arm and it would do as instructed. The boundaries of what it is capable of is wider than anticipated. As the industry evolves and develops, the tools could be easily upgraded and or replaced, yet the main machine still as is. Updating the robot program or software always keeps up to date the most advanced process it could be.

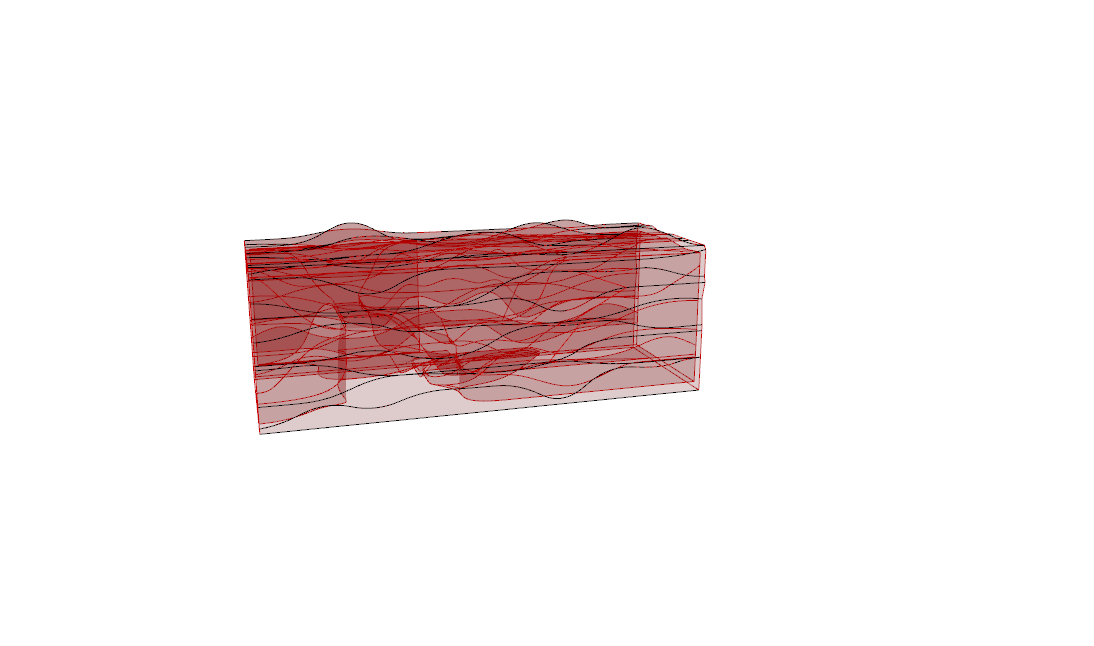

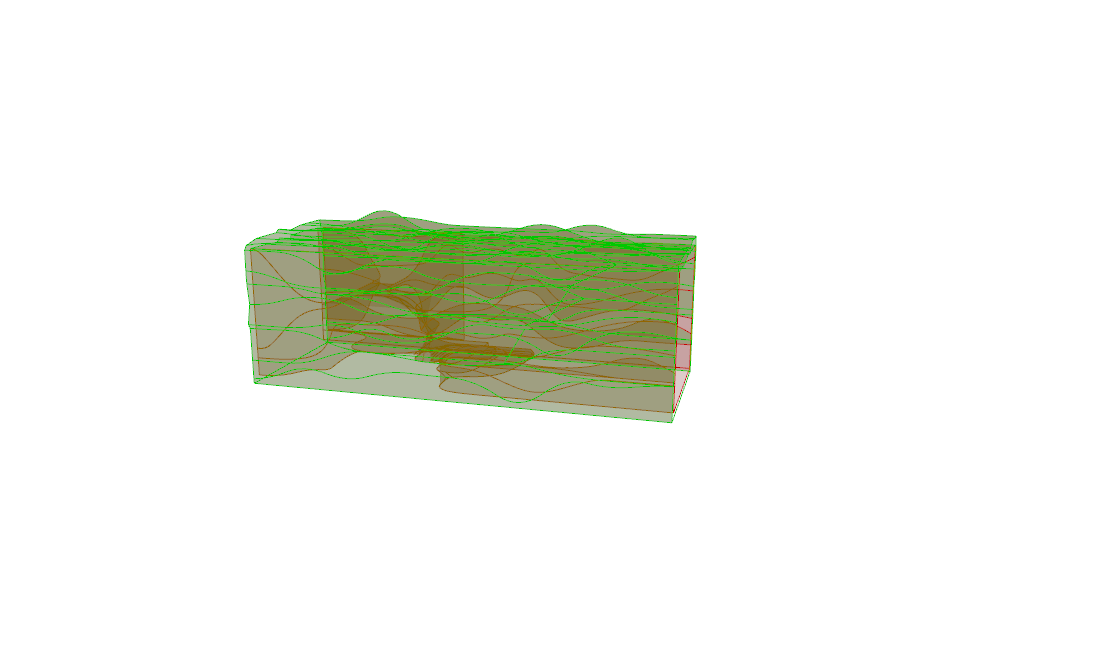

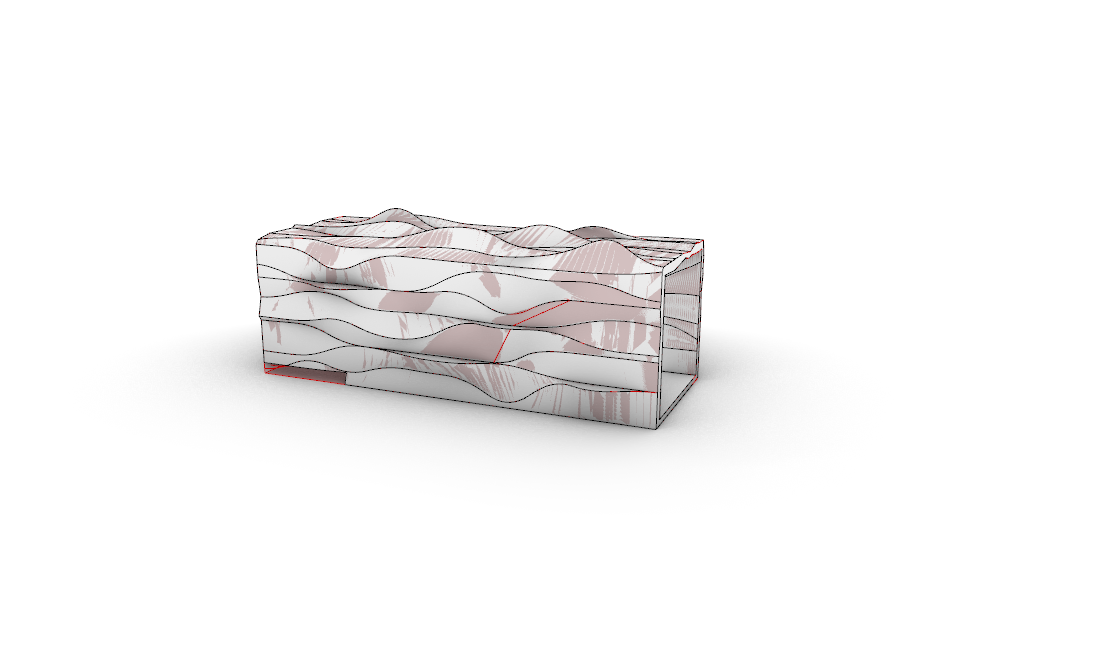

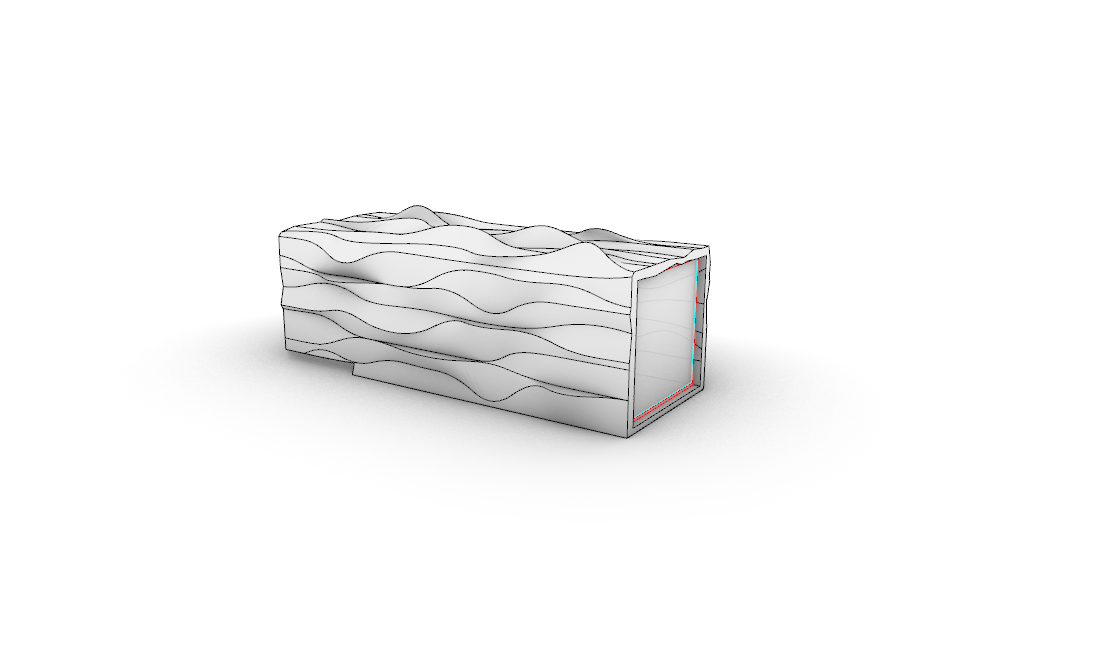

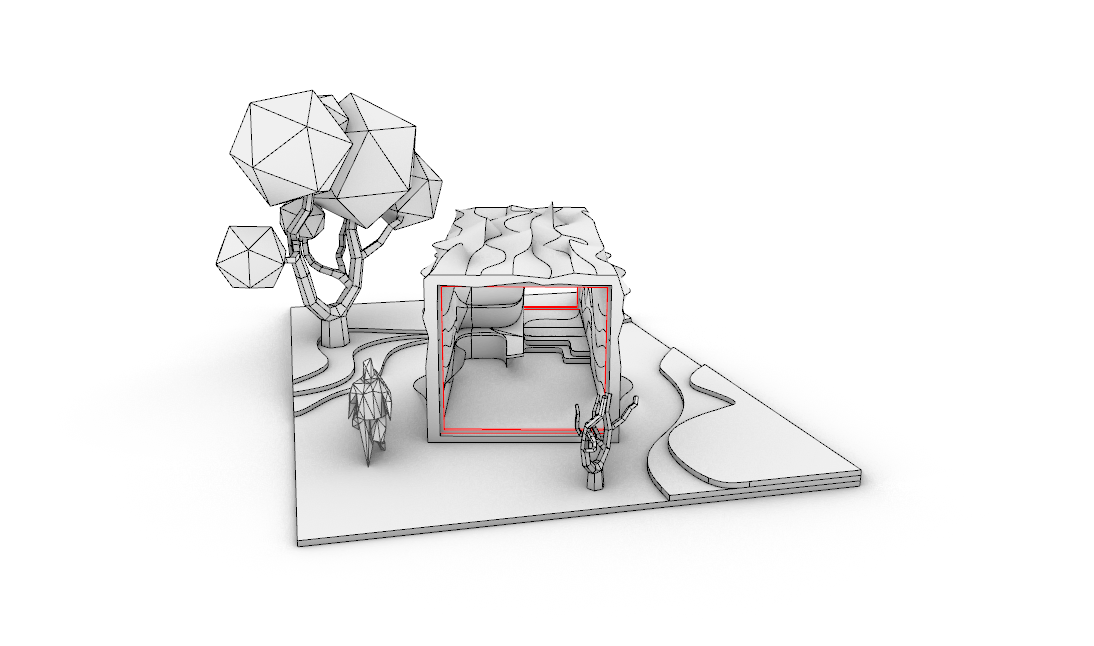

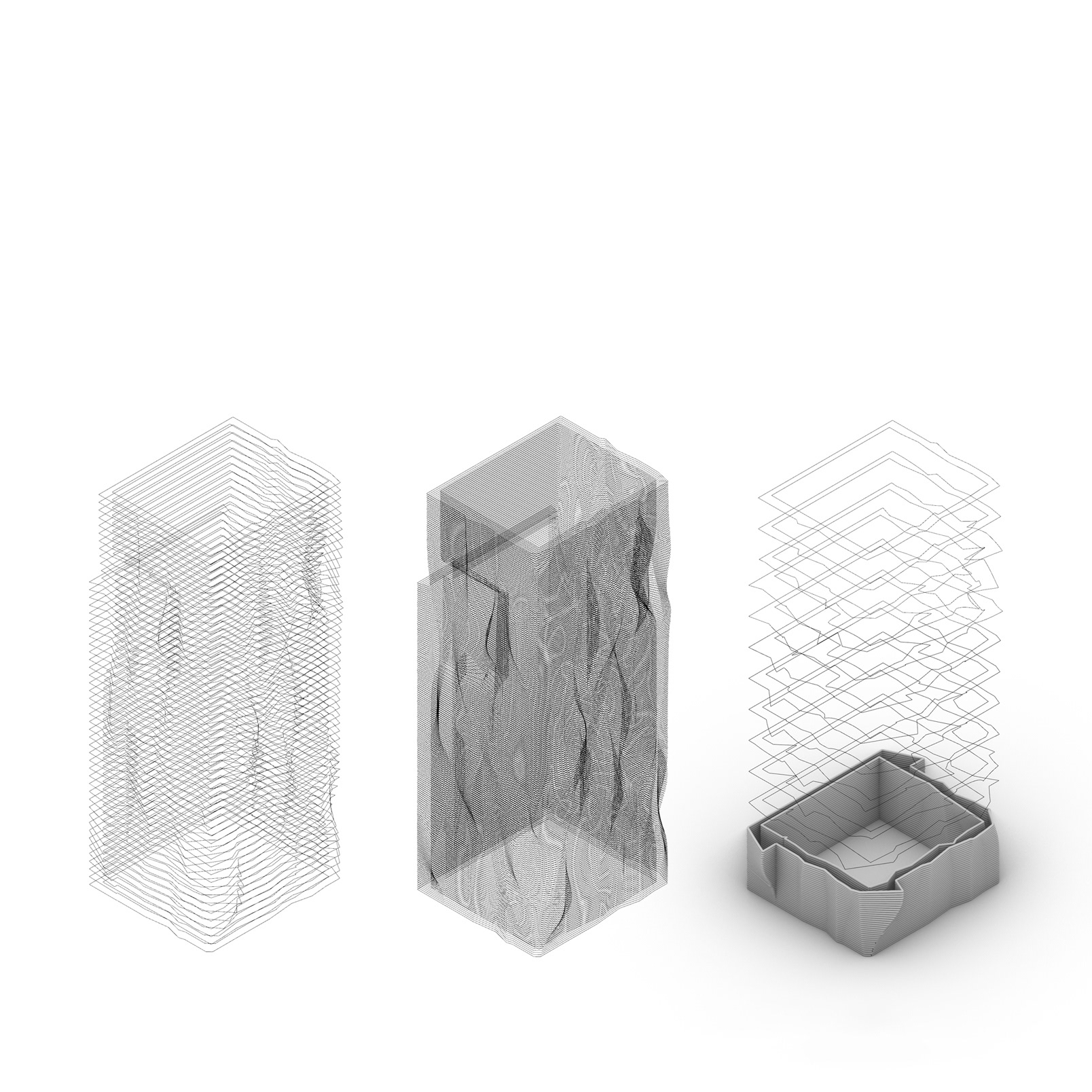

Each tool would come with its own algorithm to perform that specific task. Additive processing is different that subtractive processing. Additive would require the tool to deposit material as it moves. On the other hand, subtractive would only need the tool fixed and perform on an existing body of material like carving or sculpting.